📦 Unboxing & Initial Review

Watch our detailed unboxing experience and first impressions of the SF-Mobile WeldStar

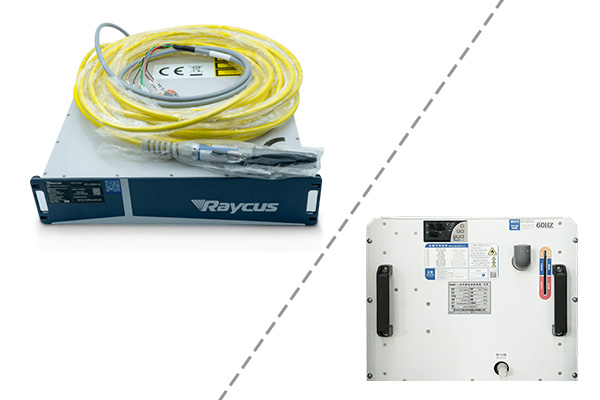

⚡ Complete Feature Overview

Comprehensive demonstration of features, capabilities, and technical specifications

Watch our detailed unboxing experience and first impressions of the SF-Mobile WeldStar

Comprehensive demonstration of features, capabilities, and technical specifications

Since introducing SF-Mobile WeldStar, our on-site installation efficiency has increased by over 30%! The equipment is extremely portable, allowing a single technician to easily bring it to customer sites, solving the problem of immobile large equipment. The welding quality is consistent, and customers are very satisfied.

Our company had high requirements for welding quality and previously used traditional welders that required experienced masters to operate. After purchasing SF-Mobile WeldStar, even new employees can operate it after simple training, and the weld appearance is actually better, eliminating a lot of grinding work and greatly improving production efficiency.

As a small advertising sign workshop, we have limited space and variable order types. The SF-Mobile WeldStar is lightweight and flexible, doesn't take up space, and most importantly, produces fine and beautiful welds that fully meet our high-quality sign production needs. The return on investment has exceeded expectations!

Requires professional skills, long training cycles, high labor costs

Cannot meet mobile operation needs, difficult workstation transitions

Slow speed, large post-processing workload, limited productivity

Serious material deformation, affecting product quality and appearance

Using advanced laser welding technology combined with ergonomic portable design, SF-Mobile WeldStar redefines the possibilities of mobile welding. Whether for on-site installation, multi-station operations, or precision welding, it can be your reliable assistant.

Select from deposit tiers ($500-$1,800) and earn bonus credits with boost multipliers!

📋 See detailed pricing table below for all models and final prices

| Region | Delivery Time |

|---|---|

| West Coast | 1-2 days |

| Southwest | 2-5 days |

| Northwest | 3-6 days |

| Midwest | 4-6 days |

| Southeast | 5-7 days |

Special Requirements: If you need lift gate service or inside delivery, please mention during checkout. We'll coordinate with our logistics partner to ensure smooth delivery.

Choose your deposit level and get bonus credit toward your final payment!

* Credit = Deposit × Boost Multiplier — automatically deducted from your remaining balance when the machine lands in Los Angeles.

⚠️ Note: This deposit boost promotion can be combined with other discounts.

⏳ Deadline: Deposit boost promotion ends on August 10.

| Laser Power (W) | 800 | 1200 | 1500 | 2000 | 3000 |

|---|---|---|---|---|---|

| Max Welding Thickness | ≈1.2 mm | ≈1.9 mm | ≈2.6 mm | ≈5.0 mm | ≈7.0 mm |

| Parameter | Air Cooling | Water Cooling | |||

|---|---|---|---|---|---|

| 800 W | 1200 W | 1500 W | 2000 W | 3000 W | |

| Weight (Kg) | 103 | 107 | 192 | 201 | 211 |

| Dimensions (L×W×H mm) | 1083×516×1185 | 1083×516×1185 | 1441×760×1185 | 1441×760×1185 | 1549×760×1185 |

| Power Supply | 220V Single Phase | 220V Single Phase | 220V Single Phase | 380V Three Phase | 380V Three Phase |

| Power Consumption (kW) | 2.5 | 3.8 | 6.8 | 8.6 | 12.8 |

| Shielding Gas | Nitrogen/Argon, Purity ≥ 99.5%, Gas Pressure: 3-5 Bar | ||||

The SF-Mobile WeldStar features an integrated trolley and gas holder design, making it easy to move around your workshop or job site. This exceptional mobility allows you to bring precise laser welding capabilities exactly where you need them.

With its intuitive interface and simplified controls, SF-Mobile WeldStar reduces the learning curve significantly. Even operators with minimal experience can achieve professional-quality welds, while experienced welders can maximize productivity.

Beyond just welding, your SF-Mobile WeldStar offers professional-grade cleaning and cutting capabilities. This versatility eliminates the need for multiple machines, saving you space, money, and maintenance overhead.

The precision laser technology produces beautiful, clean welds that require minimal post-processing. Enjoy reduced deformation, minimal heat affected zones, and exceptional aesthetic results on a wide range of materials and thicknesses.

Heavy and bulky equipment, difficult to move around

Complex operation requiring extensive professional training

Limited material compatibility and thickness range

Poor weld quality requiring extensive post-processing

High energy consumption and operating costs

Single-purpose equipment with limited functionality

No after-sales service guarantees or long-term warranties

Lightweight, compact design with built-in trolley & gas holder

User-friendly interface, minimal learning curve

Wide material compatibility: SS up to 8mm, CS up to 8mm, Aluminum up to 7mm

Clean, precise welds with minimal deformation, no grinding needed

Energy-efficient design, 40% less power consumption

Multi-functional: welding, cleaning and cutting integrated

FREE North American customized feeding wire spool holder and gas tank inlet connection

2-year warranty with localized technical support

One machine, multiple functions to meet all your metal processing needs

Precise corner joining for inside and outside angles

Perfect edge-to-edge alignment for seamless joining

Precise point joining while maintaining workpiece integrity

Overlapping material joining with superior strength

Direct material contact to effectively remove weld marks for a bright finish

Non-contact cleaning method for effective surface treatment from a distance

Precise cutting of thin materials with no deformation and burr-free edges

SF-Mobile WeldStar integrates welding, cleaning, and cutting functions into one system, significantly improving work efficiency, reducing equipment investment costs, and providing a one-stop solution for your metal processing needs.